Plasterboard walls are frequently used to create new internal or partition walls, by fixing plasterboard (or similar material) to either a metal or timber framework. Typically using anything from 9-30mm board with a slight degree of flex, plasterboard walls have a lower load bearing capacity compared to solid walls made of brick or concrete, for example. There are lots of types of plasterboard fixings available and it’s important to use the correct type. When choosing a fixing, we advise taking into consideration the following;

- Application – The type of item you need to fit and how heavy it is at its maximum (for example, if it’s a radiator, the weight when it’s full).

- Type Of Load – Items fixed flat to the wall such as TVs will induce significantly less load than the leverage of a floating shelf.

- Wall Type – What type of plasterboard wall you have e.g. the board material, how thick it is, is it single or double layered, is it insulated or is it tiled over the top?

- Fixing – The weight capacity per plasterboard fixing and if it is suitable for your wall type.

Below are some of our recommendations for high quality plasterboard fixings, split into weight categories.

Plasterboard fixings for light duty items

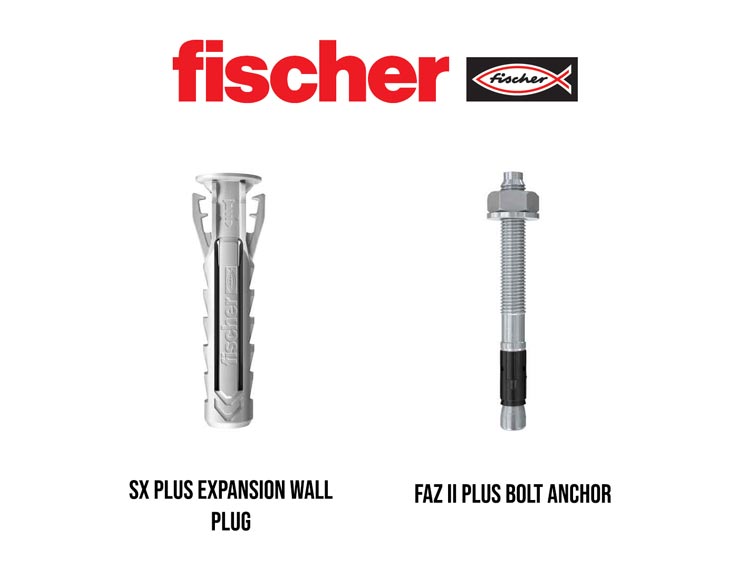

fischer HDPF Plasterboard Wall Plug – a simple, economical wall plug for very lightweight items such as pictures, up to 4kg.

fischer PDM Metal Plasterboard Wall Plug – a self tapping wall plug with a sharp metal thread, meaning you do not need to pre-drill a hole. Ideal for lighting, electrical installations and pictures for example, with a rating of up to 7kg per plug.

fischer Duoblade Plasterboard Wall Plug – a premium version of the PDM plug. The Duoblade is self drill and made from nylon with a metal tip. It is also suitable for use in double layered plasterboard and cement board. Will hold up to 10kg per fixing in 12.5mm single layer plasterboard, so can hold slightly heavier items such as mirrors, curtain poles and smoke detectors.

Plasterboard fixings for medium duty items

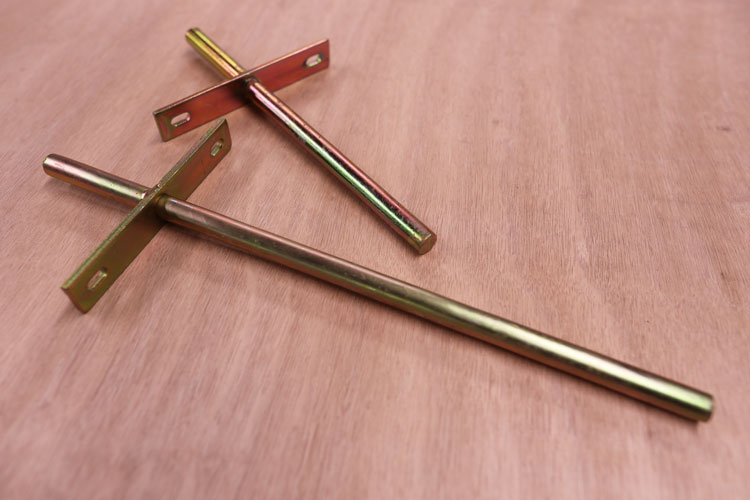

BespOak Interiors Multi-Wall Concealed Floating Shelf Fixing (Plasterboard Variation) – specifically for fitting floating shelves up to 150mm deep to plasterboard. Rated up to 6kg per fixing, with a minimum recommendation of four brackets per metre.

fischer DuoPower Wall Plug – a premium wall plug that cleverly adapts to the wall type, including plasterboard (others include brick, stone and chipboard). Weight capacity varies from 10kg-50kg per plug depending on the size of DuoPower used and the wall type. Use for blinds, curtain rails, letter boxes and small cabinets, for example.

Timco Metal Cavity Anchor – a completely metal fixing with multiple expanding arms to secure it in place. Weight capacity varies from 22kg-37kg per anchor depending on size, based on 12.5mm plasterboard. Timco suggest using these for hanging radiators, brackets, hand rails and shelving units.

Plasterboard fixings for heavy duty items

fischer DuoTec Toggle Fixing – each flip toggle fixing can support between 17kg-130kg of weight. (Note – the final weight rating depends on the screw size used and type of board it’s fitted into.) The DuoTec is suitable for plasterboard, fibreboard and wooden panels. It also functions as an expansion plug in solid material. This is ideal if you hit a timber batten behind the board. Use for wall cabinets, shelves, wardrobes and lamps, for example.

GripIt Plasterboard Fixing – a unique fixing with slim, gripping wings. These can secure heavy loads ranging from 74kg-113kg, depending on the variation of GripIt used. GripIts are recommended for fitting items such as radiators, boilers, cabinets and speakers.

What about fitting into the battens/studwork?

Most plasterboard fixings aren’t suitable to fit into the battens/studwork behind the plasterboard. Out of the ones listed above, the fischer DuoTec Toggle Fixing and our Multi-Wall Concealed Floating Shelf Fixing (which uses the DuoTec as one of its components), are the only ones that you can also install into timber.

If you are intending to fit solely into the battens rather than the plasterboard itself, then we recommend using a fixing designed for solid walls/solid material.

If you need some help choosing your fixing, please contact us and we will do our best to advise you.

A 200mm depth is what we would consider a standard depth floating shelf. Great for plants, bigger ornaments and standard sized books, these are great size wall shelves for everyday use. However plasterboard floating shelf brackets are generally not able to support this depth, due to the leverage placed upon the plasterboard. Therefore we only recommend the

A 200mm depth is what we would consider a standard depth floating shelf. Great for plants, bigger ornaments and standard sized books, these are great size wall shelves for everyday use. However plasterboard floating shelf brackets are generally not able to support this depth, due to the leverage placed upon the plasterboard. Therefore we only recommend the  275mm deep is the point at which we upgrade the floating fixings to heavy duty ones. These

275mm deep is the point at which we upgrade the floating fixings to heavy duty ones. These

How to fit a floating shelf with our

How to fit a floating shelf with our  How to fit a floating shelf with our

How to fit a floating shelf with our